Low deadweight, easy to position

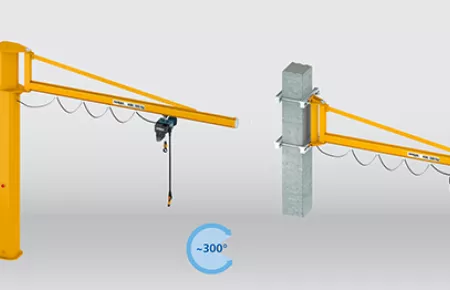

KBK pillar-mounted slewing jibs

Switch to improved productivity and ergonomics

Manually handling and combining or moving relatively light loads is often not only time-consuming, but also an ergonomic burden for employees. Together with a wide selection of hoist units, our slewing jibs and cranes installed direct at the workplace enable all types of workpieces to be lifted and transported quickly and easily and deposited gently and precisely. In this way, setting up and idle times can be significantly reduced and periods of waiting for workshop cranes to become available can be completely eliminated. Further strengths of our pillar and wall-mounted slewing jibs include:

- Further strengths of our pillar and wall-mounted slewing jib cranes:

- light and fast load handling

- ease of operation and high operating safety and reliability

- load capacities up to 10,000 kg

- simple installation using fittings included in the system

Product information

The benefits at a glance

Comprehensive crane product range

- Safe and reliable material flow

- Optimum workplace design

- Simple operation

- Ergonomic handling

- Complete solutions for your specific needs from a single source

- Highest possible quality standards

- Broad spectrum of load capacities and outreach dimensions

Series slewing jib cranes

Pillar and wall-mounted slewing jib cranes with KBK jibs, braced design

Light-weight design, low travel forces: Slewing jib cranes that have a braced KBK jib feature high load capacities and outreach in relation to their deadweight. Its low weight enables the jib to be moved with ease, even under load, for ergonomic handling. The proven KBK hollow section rail as the crane girder also provides for very low travel forces.

This light-weight design is ideally suited for all workplace material flow requirements and handling loads weighing up to 1,000 kg.

Capacity and outreach

| Load capacity [kg] | Outreach [m] | ||||||||||

| 2 | 3 | 4 | 5 | 6 | 7 | ||||||

| 80 | x | x | x | x | x | x | |||||

| 125 | x | x | x | x | x | x | |||||

| 250 | x | x | x | x | x | x | |||||

| 500 | x | x | x | x | x | ||||||

| 1000 | x | x | x | x | x | ||||||

Pillar and wall-mounted slewing jib cranes with I-beam jib, low-headroom design

Long hook paths, low headroom dimension: slewing jib cranes equipped with low-headroom I-beam jibs are suitable for universal applications over the entire load capacity range up to 2,000 kg. Thanks to their compact dimensions, they are the ideal solution for situations where long hook paths are needed in spite of a low ceiling height.

Capacity and outreach

| Load capacity [kg] | Outreach [m] | ||||||||||

| 2 | 3 | 4 | 5 | 6 | 7 | ||||||

| 80 | x | x | x | x | x | x | |||||

| 125 | x | x | x | x | x | x | |||||

| 250 | x | x | x | x | x | x | |||||

| 500 | x | x | x | x | x | x | |||||

| 1000 | x | x | x | x | x | x | |||||

| 1600 | x | x | x | x | x | ||||||

| 2000 | x | x | x | x | |||||||

Pillar and wall-mounted slewing jib cranes with I-beam jib, braced design

Long outreach, low deadweight: the braced jib design enables long outreach dimensions to be achieved for a low deadweight, which provides for easy and ergonomic manual operation for all outreach variants.

Smooth lifting and lowering motions as well as precise positioning with these slewing jib cranes enable you to handle sensitive and valuable loads gently and to avoid damage. For load capacities up to 2,000 kg.

Capacity and outreach

| Load capacity [kg] | Outreach [m] | ||||||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||||

| 80 | x | ||||||||||

| 125 | x | ||||||||||

| 250 | x | ||||||||||

| 500 | x | x | |||||||||

| 1000 | x | x | |||||||||

| 1600 | x | x | x | x | |||||||

| 2000 | x | x | x | ||||||||

Pillar and wall-mounted slewing jib cranes with two KBK jibs, braced design

Pillar-mounted slewing jib cranes fitted with two jibs are highly effective solutions: they take up the same space as slewing cranes that have one jib – but offer double the performance. Both jibs can be arranged opposite each other to create two neighbouring working areas. In this way, the efficiency of specific process sequences can be improved even further.

| Load capacity [kg] | Outreach [m] | ||||||||||

| 2 | 3 | 4 | 5 | 6 | 7 | ||||||

| 80 / 80 | x | x | x | x | x | x | |||||

| 125 / 125 | x | x | x | x | x | x | |||||

| 250 / 250 | x | x | x | x | x | x | |||||

| 500 / 500 | x | x | x | x | x | ||||||

| 1000 / 1000 | x | x | |||||||||

Classification of all series slewing jib cranes to DIN15018 H1B3.

Special slewing jib cranes

Pillar and wall-mounted slewing jib cranes with I-beam jib, low-headroom design

High load capacities, large outreach dimensions: these slewing jib cranes offer high load capacities up to 10,000 kg for large outreach dimensions. The low-headroom jib provides for particularly long hook paths. The unlimited slewing angle offered by the pillar-mounted slewing jib crane is a major benefit, especially for large working areas.

However, the wall-mounted slewing jib cranes also provide a broad range of applications.

| Load capacity [kg] | Outreach [m] | ||||||||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||

| 125 | x | x | x | x | x | x | x | x | x | x | x | ||

| 250 | x | x | x | x | x | x | x | x | x | x | x | ||

| 500 | x | x | x | x | x | x | x | x | x | x | x | ||

| 1000 | x | x | x | x | x | x | x | x | x | x | x | ||

| 2000 | x | x | x | x | x | x | x | x | x | x | x | ||

| 3200 | x | x | x | x | x | x | x | x | x | x | x | ||

| 4000 | x | x | x | x | x | x | x | x | x | x | |||

| 5000 | x | x | x | x | x | x | x | x | |||||

| 6300 | x | x | x | x | x | x | |||||||

| 8000 | x | x | x | x | x | ||||||||

| 10000 | x | x | x | x | |||||||||

Classification of all special slewing jib cranes to DIN15018 H2B3.

Equipped with Demag chain or rope hoists as standard

Options

Options for even more possibilities

- Hoists with electric travel

- Locking device to secure the jib in a specific position

- Electric slewing drive for particularly smooth slewing motions

- Radio control

- Alternative surface coatings – e.g. for outdoor operation

- Specific pillar heights for all pillar-mounted slewing jib cranes

Slewing motion limiter

An adjustable slewing motion limiter can be installed to limit the

slewing range of the jib, as required. The clamp-fitted design also enables it to be installed at a later date.

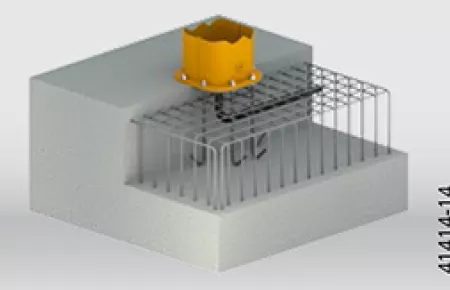

Pillar connections

Anchors are used to fix pillars to the foundations. A template is used for precise alignment of the anchors with the mounting holes in the base of the pillar when the foundations are laid.

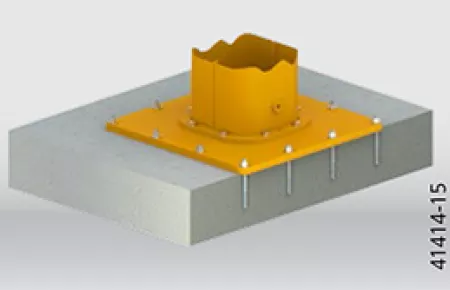

Anchor bolts are used to attach a pillar to an existing concrete floor. Chemical anchor bolts are first used to install an anchor plate to which the base of the crane pillar is then attached. This anchor variant is highly suited for relatively thin concrete floors that have a thickness ≥ 200 mm.

Wall mounting arrangement: pillar brackets can be used for simple attachment of wall-mounted slewing jib cranes to a wide range of pillar dimensions. They can be attached at the required height to all square-section pillars.

All wall and pillar connections for Demag slewing jib cranes offer maximum safety and ease of installation.